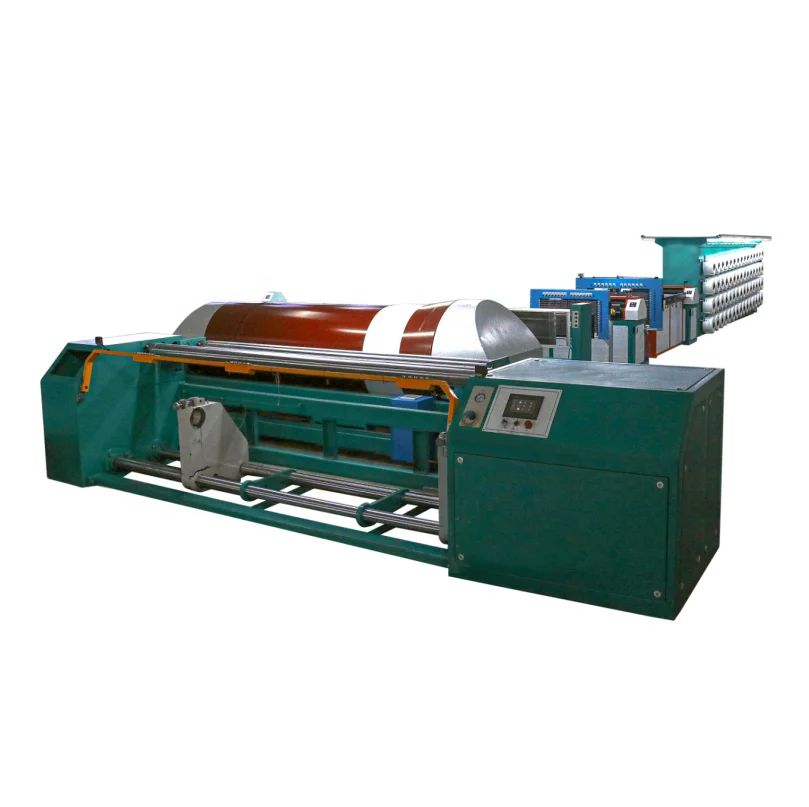

How efficient and productive a textile manufacturing unit can be, this will depend upon the supply of sectional warping machine supplier The importance of these machines and their role in the preparation of warp yarns for weaving ultimately influence both quality, as well as the rate at which manufacturing takes place. There are scary numbers of choices that can be found on numerous suppliers and you might not know what the best choice for you. However, if you analyse the correct elements and listen to real world experience carefully, one will add an asset in business building by having a supplier.

How to choose a supplier for sectional warping machine 2019 - the most crucial aspect

1. Information technology and Breakthrough Technology

Begine by assessing the tech prowess & innovation of your strategic suppliers. There have been numerous technological developments in recent years and a supplier who takes advantage of this is likely to be significantly ahead. Therefore, the machines they supply will feature technologies that help keep downtime low, consume less energy or produce higher quality yarns. Those suppliers with refreshed product lines, which are more and more driven from automation on technology-savvy bases will survive the competitive landscape.

2. Quality and Durability

One way to show this is through the thickness of things like metal construction and build quality. Request samples or visit another client site to see the machines in operation. This is further enhanced by full steel contruction and best in class materials to ensure you get ultimate reliability for operational use, as well quality warp beams that stand the test of time.

3. Post Sale-Service Support

When operational issues do arise, which in practice is bound to happen from time to time prior-to and post-purchase can be a gamechanger. Analyze the services of your provider, response times and spare parts supply. This simply means the closer to where you are based, your supplier has a presence or an international support infrastructure deployed from there enables them to get you running again faster in case of downtime.

How To Choose A Reliable Warping Machine Supplier

Request a complete full rig demonstration in...your yarn (best) and just generally to evaluate performance & compatibility. Having this hands-on early experience will allow you to assess intuitiveness, range of adjustability and capacity for different yarn counts and types. A supplier who backs its product will gladly arrange these demos, the tech team should be glad to participate in face-to-face discussions.

Textile machinery suppliers at the front line of adjustment

Subscribe to industry events, trade shows and also online forum for you where the titans of innovation deliver. While ongoing engagement in such platforms shows suppliers are receiving new opportunities for development and knowledge-sharing, indicating that they want to move the industry forward with them. On the other hand, networking amongst fabrics in a textile-centric community can lead you to discover suppliers with highly specialised knowledge about luxury fabric and superb customer reviews. Where Networking Is Your Sourcing Stopper

Dependencies on international vs. domestic suppliers

The decision to use an international or domestic supplier depends on several things. Many times, international vendors offer better prices and more cost-effective technologies which are new to the home country. Transactions are difficult, however, due to language barriers and long shipping times as well as different import regulations...and obviously risky too! In comparison, it is faster than a delivery to the domestic suppliers - they are easier to talk with Chinese companies: in your market things go can just gonna be better. Now Evaluate the top priorities (most important- cost effective, Innovation or Service at Speed) and choose accordingly.

Decision: The Voice Based on Direct Customer Experience

Find reviews & testimonials of their clients. This allows the user to glean insight into vendor reliability and machine functionality in addition to obtaining an overview of another human operator's experience. Communicate with people relevant to where you operate. Similarly, much can be learned from social media platforms and niche review sites where unbiased sources share their opinions. Just bear in mind, the more satisfied customers a supplier has on their track record is going to get better at meeting your needs.

To sum up, one should put some time and thoughts while selecting the manufacturer of their sectional warping machine. When it comes down to prioritising tech, you really do have a lot across the board to weigh up from durability & after-sales support all of the way through industry leadership and real-world customer experience & peer review when deciding your choice-best-fit-enabling partner for an ever more efficient profitable process making textiles. It makes sure that it not only provides a high-performance machine but also helps keep the floor humming with activities and transactions in its lively nature of fabrics.

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE