How to choose for a good sectional split warping machine manufacturer

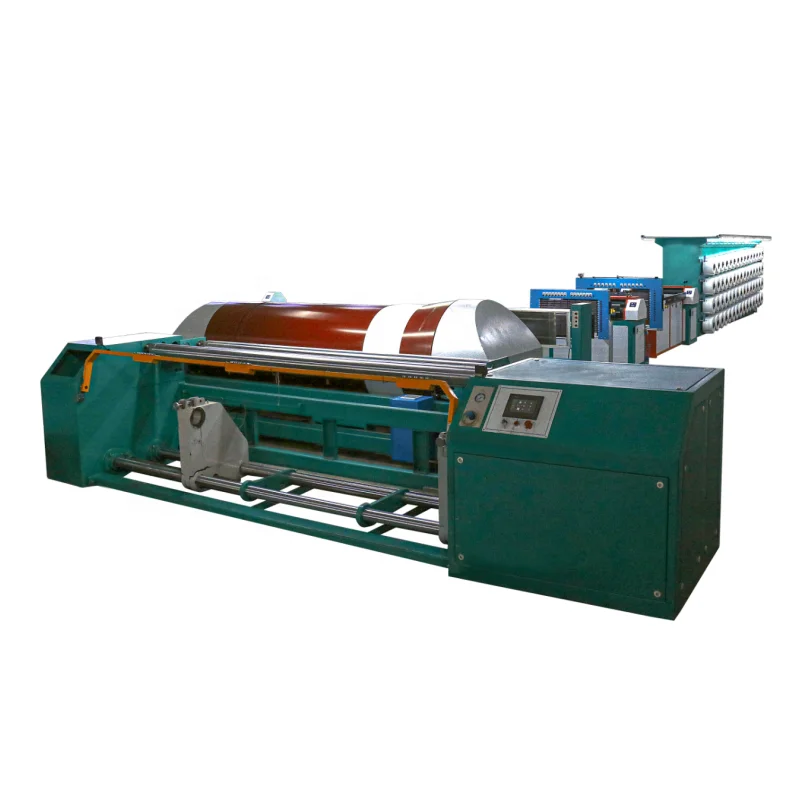

Sectional split warping machine This equipment is particularly used in textile industry where manufacturers are to warp the yarn for weaving or knitting purposes. With so many manufacturers having different models, choosing the right one could be quite a headache. This comprehensive guide will help you choose the right way for yourself.

Benefits of Sectional Split Warping Machines

There are a lot of benefits offered by this kind of sectional split warping machines. These machines give you the option of twisting multiple strands at one time, which in turn saves your time and increases overall productivity levels. These split warping machines also allow you to create more uniform warps, thereby minimizing errors and making better-quality fabrics.

Innovation In Sectional Split Warping Machines

Sectional spit warping machines are also manufactured by some with the element of innovation. Top tier manufacturers invest in research and development to improve their machines from extended functionality, precision control capabilities and increased productivity. If you are looking for computerized tension mechanisms or ability to adjust the yarn tension automatically, then manufacturers using Latest innovative technology could be a good potential choice.

Sectional Split Warping machines Safety Pros

Safety comes first in the purchase of a sectional split warping machine. Cnc milling machine is obligatory to have safety measures such as emergency stop buttons, safeguarding interlocks protective shields etc., which ward off any mishap or injury so take consideration of it very seriously. Buy from companies which follow national safety standards and have specific quality control measures to ensure the safety of their products.

Service Guide for Sectional Split Warping Machine

It is not too complicated to operate a sectional split warping machine, but it does need some skill. The manufacturer conducts how to enable and use training sessions in the system for clearer understanding. If you wish to use them, make sure your machine is clean and greased up before mounting the parts. One of the most crucial aspects is loading and unloading yarn properly as indicated in the manual. To keep a machine running, maintenance cycles go hand in hand and are very important as they will help the machine to perform at its best level.

SA-DOQuality OF Sectional-Split Warping Machines

Use of a Sectional Split Warping Machine Offers Enhanced Features: It is obvious now that the quality has an indisputable impact on how long it lasts and also how much you are getting off your end product. Look out for companies who use high quality materials to built, like cast iron or steel. Machines components should be made of high-quality metals to ensure durability and sustainability. A warranty, if sold by the manufacturer can be a real nice comfort to have when buying.

Sectional Split Warping Machines Applications

Sectional Split warping machines are widely used in the textile industry to warp yarn for weaving or knitting. They are used in making garments, upholstery, carpets and other materials such as tents. Choose machines that work with a wide variety of yarns and in various thicknesses, making it easier for companies to produce different types of fabrics.

In Conclusion

The right sectional warp splitting machine manufacturer ensures that the machines it sells meet your requirements and are equipped with advantages, safety features, innovation, quality and applications. Top manufacturers have patented research and development ventures for high caliber machines, in addition to service guarantees Research as much as you can, read reviews and check the reputation of your manufacturer before buying it. A sectioned split warping machine is the perfect component that can take your textile production processes to a higher level while benefiting substantially on your bottom line.

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE