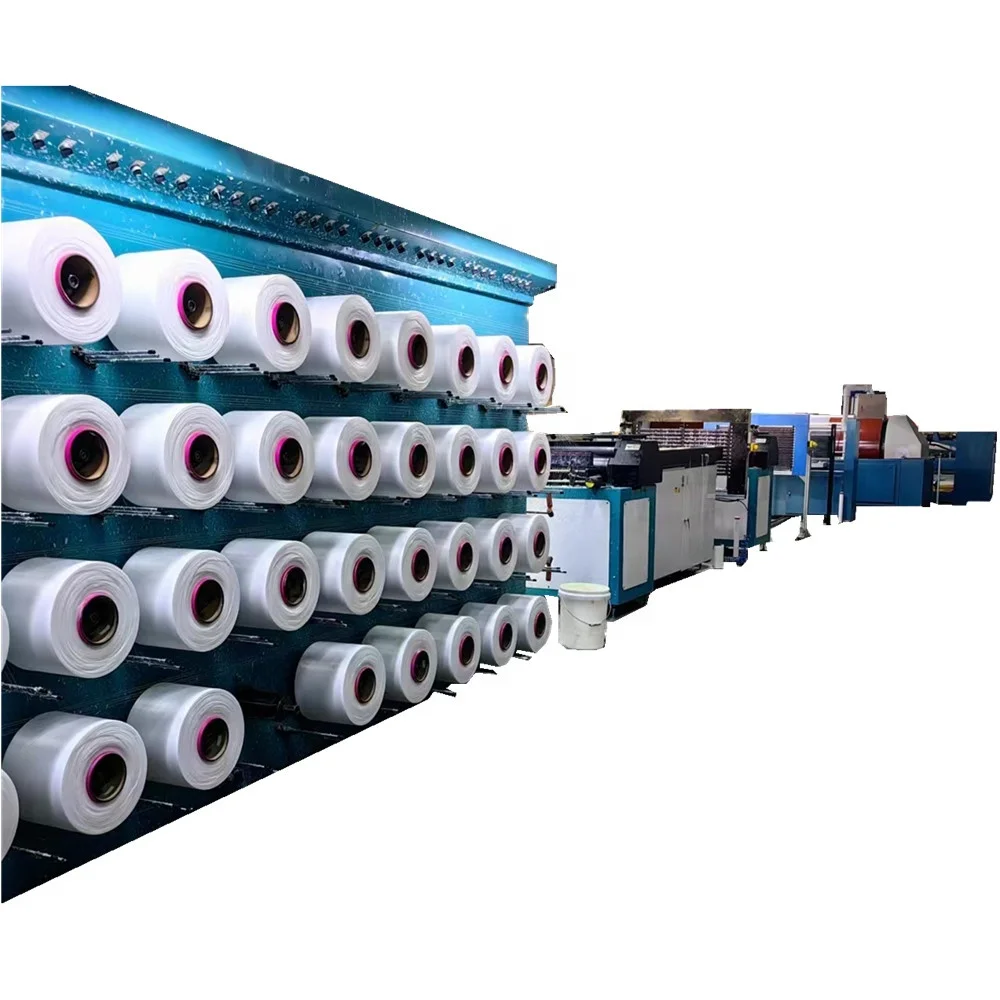

There are many factories manufacturing splitting warping machines in India. Spinning machines are amazing as they prepare (by twisting) yarn, a long strand composed of fibers used in spinning cloth. It will be very difficult to make the fabric we need for clothes and several other items a day without this machines. Now let's see 7 of the best Indian factories serving this machinery.

The best factories make good machines

The top factories of Splitting warping machines in India is best known to create them with new and contemporary technology. They take a look at every single component of the machine to do everything in its power for providing supreme compatibility and functionality. The meticulous attention to detail ensures that the machines run smoothly and effectively. Factories work very hard to create the greatest machines they can and are proud of their machines.

High Quality and Efficiency

The most outstanding factories that manufacture splitting warping machines in India are extremely proud of not only the strength and effectiveness with which they have been able to construct every machine, but also with their overall functionally. If we say the machines are efficient, it means they perform very well but do this at a fraction of an energy. We want to do this because we waste less, and it is better for the planet. Furthermore, because they are durable devices that can last for long periods of time; they do not require frequent replacement. They are also user-friendly so the workers to handle these machines. They are just searching for new possibilities in enhancing their equipment, which indicates all they care is quality and progress.

Making Yarn Ready for Cloth

Beam warping machines are used to prepare yarn for weaving and cloth production, whether of a staple spun or silk fibrous nature. Said preparation work must be done to a high level so that the cloth comes out nicely. All the top bins manufacturers in India ensure that their machines are capable of performing this function perfectly. They apply their craft of making machines that manipulate the yarn to where it needs to go, and then is finally ready for you or I (the end user) as a consumer/cloth manufacturer.

New Ideas for Better Machines

India has many world class manufacturing companies made Splitting Warping machine in India factories. However, they never stop coming up with new ideas on how to improve their machines. This means they have an inside track on what is currently trending in technology, and are also at the forefront of making high-end machines. Those factories are the genuine pioneers in textile machinery industry and they have never paused to step ahead by introducing a new element or improving on an old feature.

Seven Great Factories

All the seven factories in India which manufacture, Splitting Warping machines are unique. These highly productive and state of the art factories are good in quality, outputterns as well craftmanship for each machine they produce from their factory. All the utilize modern technology and have some great ideas that set them apart. These machines are designed, created and operated by those who so happen to understand the needs of global textile producers; thus make machines that run perfectly. These factories play a significant role in the global textile industry as many industries depend on their machinery to manufacture fabric.

Finally, India is home one of the more prominent manufacturers of splitting warping machines factories in the world. They employ state of the art technology and stringent manufacturing procedures in order to build some truly top notch pieces. These devices are planned wonderfully to set the yarn prepared for cloth making. These factories are paving the way in cutting-edge textile machinery, and machines made by the top seven factories help to all of these multinational suppliers of textiles. They distinguish themselves due to their level of commitment towards excellence and innovation that add value, thus become vital for the industry.

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE