Direct warping is a rare but interesting technique to create the fabric that in doing so produces stunning patterns and designs. Groups of artisans and artists worldwide become accustomed to using this profixM direct warping and sectional warping for their creations, focusing on luxurious textiles adapted not only in their function but also in decorative touch of various cultures. We also give a step by step no prior equipment revolutionary warping method. And we'll throw in some of my most beloved direct warping hacks, as well as a few novel ways to weave.

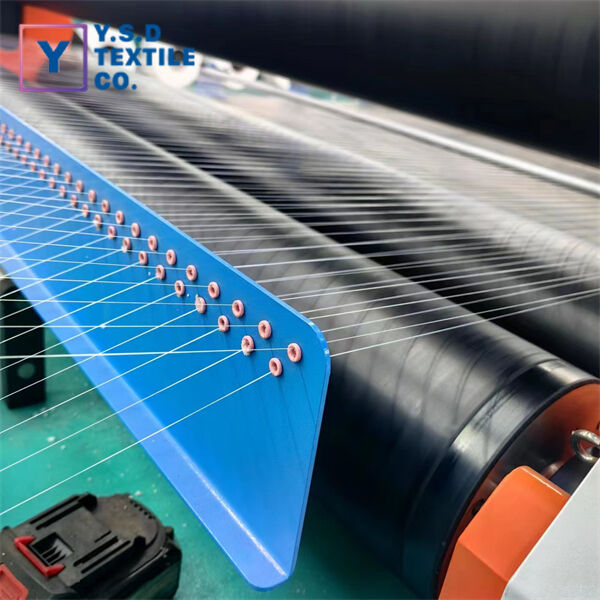

On the other side direct warping is a method of creating the warp in exactly where it will applied to weaving which equals on a loom. Therefore, when you weave using this warp and wrap yarn is in place fibers are aligned so more intricate designs can be woven into the cloth. Direct warping - You measure the exact amount of yarn you need and wrap it on a warping board. Simply put, a warping board is a large square frame with pegs sticking out of it. Yarn is looped back and forth across these pegs to create rows of loops that will become the warp. Step 3 place Carefully All Loop from Pegs off and move in to loom gang on the needed length of yarn.

Direct warping gives numerous benefits over the other various methods. First of all, this allow you to be in charge with the warp and your designs would be more accurate and consistent. Save time: Secondly, if you aren't a fan of using other tools such as a warping mill (they can be quite bulky) profixM direct warping machine does save a lot of time. Finally, the technique lets you see what your final product will look like so that you can weave faster. This will let you see your design as you work on it, making it easier to modify things and make sure they look good.

Measure out your yarn to the correct length using the warping board and carefully place it on the board Wrap your yarn around all of pegs trying to keep it tight and uniformly spaced.

Unmeasured warps: Wraps Clamp off the loops from the warp board as they are done and transfer them to the loom. Tie the ends of your yarn to the back side of your lovely loom better than before and with a little bit of gris-gris using these.

With some attention to the other web form how tight the thread winds, you will achieve a beautiful direct warp! This type of winding might use a raddle because it helps to keep the yarn nice and even. It’s also very important to keep separate lines of warp and all parallel threads in the section of the warp are taut, so when getting ready to weave, all tensioned by pulling them tighter. These errors can result in error or inconsistent elements in your final fabric, so make sure to be exact and do not skip over things.

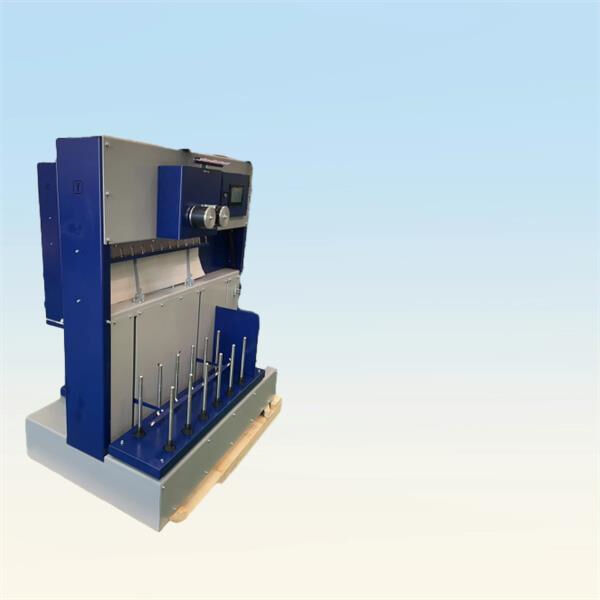

While this is an excellent direct warping method, other weavers may have already experimented with various methods and prefer to choose a different style as they see fit for their project. For example, (and let me define what a warping mill is in parentheses so you can read it!) some weavers will use a profixM mother yarn on sectional direct warping machine. Used for chaining longer lengths of yarn on to cones in preparation for moving to the loom. This is beneficial for people who are going to work with longer warps. Other will do what is call sectional warping, which means prepare smaller amounts batches of warp that they then assemble on the loom.

factory team is extremely customer-centric recognizes that the success a business is dependent on the needs satisfaction of its customers. They Direct warpinglisten the voice of customers and enhance their service production in order satisfy their requirements and expectations.

products simple to install, set up Direct warping.

supply yarn and machine more than 12 years and are a top research development department. continue new Direct warpingupgrade. also have 30,000m2 of machine production workshop 20,000m2 of nylon/polymer production workshop.Our team is dedicated providing you with the highest quality machines. Every member our team is responsible for the work they do. We sincerely hope that our technology and efforts can help you achieve greater quality of work.

company was established 2013. Our Direct warpinghas sold 300 products over the past 11 years, are the market most popular. company is a specialist company that designs, manufactures sells split-warping machines and yarn. manufacturing team brimming with practical skills and knowledge.