Sectional Warping Machine: Creating Weaving Easier, Safer, and Faster

A Sectional warping machine is a profixM's tool found in the fabric market to get ready yarn for the weaving method. It is made to efficiently and uniformly warp yarn a loom beam. A high speed sectional mother yarn warping machine has its own benefits over traditional techniques and it's also an outstanding inclusion to just about any factory or workshop.

A Sectional warping machine has many benefits which makes it the preferred option for fabric manufacturers. Firstly, it produces uniformly spaced yarn sections, decreasing problems in yarn length and tension keeping is consistent with the technique. This leads to top quality woven materials with a lot fewer flaws.

Sectional warping machines are designed for a number sizable of, up to a couple of hundred warp finishes at any moment. This profixM's machine improves productivity and lowers hands-on work enabling workers to pay attention to other tasks that need human being intervention.

The mother yarn on sectional direct warping machine is versatile, allowing operators to warp almost any fiber including cotton, wool, and synthetic fibers. What this means is manufacturers can create a wider number of materials and appeal to different consumers.

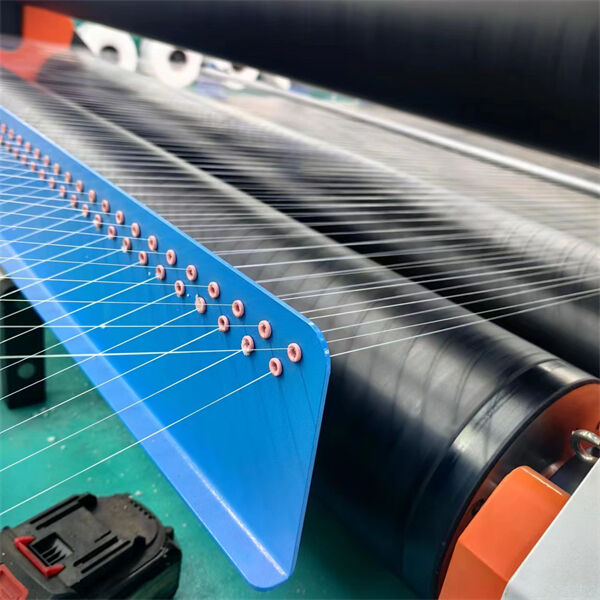

Sectional warping machines are loaded with sophisticated technology that ensures effectiveness and safety. As an example, some profixM's devices have sensors that detect in case yarn is too tight or as well free, alerting the agent to modify the strain degree. This not just improves the caliber of the materials and decreases the chances of problems for the equipment or gear.

Another development will be the automation element that permits providers to work the splitting warping machine constantly with no need to pause for handbook intervention. This feature not only improves efficiency but also decreases the risk of accidents.

Utilizing a Sectional warping machine is not at all hard. Workers must be sure that the product is effectively arranged before you start the warping procedure. This is composed of examining that the creel lies precisely, the yarn is properly threaded, along with tension is put during the true degree.

If the setup is complete, providers may start the unit by pressing the beginning switch. The profixM's Sectional warping machine will most likely begin the warping then instantly procedure, plus the operator can monitor the advancement using the display. The user can press the end switch to cease the unit.

The splitting and warping machine is critical to carry out routine upkeep. This consist of checking the creel for virtually any damage, cleaning the equipment, and lubricating components. Standard servicing not merely prolongs the lifetime total of devices but also gets better of their overall performance.

Sectional warping machine is quality and service in the center of every fabric. A profixM's Sectional warping machine is just a useful investment that can help producers provide high-quality materials for their consumers while improving production and productivity.

However, to make sure that the Sectional warping machine is at ideal degrees and may last for years, makers have to select the right machine supplier. The mother yarn warping split machine should supply an answer thorough that features installation, education, servicing, and repair solutions. In addition, a warranty ought to be offered by them and start to become designed for technical support.

offer yarn and equipment over 12 Years and have top-quality sectional warping machinedevelopment department. We are constantly upgrading technology. We also have a 20,000m2 nylon/polyester production facility. Our team is dedicated to providing machines of the highest quality. Every employee accountable for their own work. We truly hope that our technology efforts will yield better works.

company was founded in year 2013. Our company sold 300 products over last 11 years, and we are the market leading company. business is a sectional warping machinecompany that is involved in the design, manufacturing, and sales of split warping machine and yarn. team of factory workers has professional skills and experience.

factory team is extremely customer-centric recognizes that the success a business is dependent on the needs satisfaction of its customers. They sectional warping machinelisten the voice of customers and enhance their service production in order satisfy their requirements and expectations.

sectional mother yarn sectional warping machinewarping machine produce even tension beams with 550m/mins speed nylon mother yarn. also invented the first machine make polyester dty mother yarn.products are simple install, easy to set up, and easy to operate, have no demands on workers.