Warp preparation is the critical step to produce fabric. It takes the form of yarn running along the length of the fabric that contributes to its strength and stability. Doing this process manually and manually can be a lot of work for a long time. On the contrary with profixM prashant warping machine you can do this job faster and easiest.

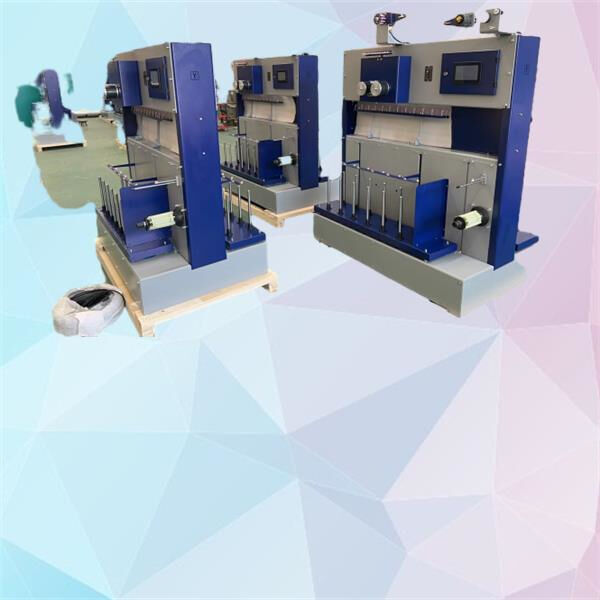

ProfixM mfg many types of Prashant Gamatex warping machine. There is a specific machine for several various yarns. Thus during the spinning process, no matter what type of yarn a factory has, it can be prepared on each respective machine. The use of the warper has a high level of technological maturity. They assist during the entire process from the time yarn comes in to the time it goes out for weaving.

Warping technology of Prashant Gamatex can be used in fabric manufacturing to improve the quality. This technology allows workers to produce more fabric in less time, thus making their job easier and more than the others were worse. They help in supporting the all yarn preparation process of s fabric which must be smooth and easy for a better quality.

Every warping process at Prashant Gamatex is designed keeping in mind that each is absolutely alike the other. It means when people are doing this warping by hand, quality may vary drastically and consequently can lead to issues down the line. But on profixM prashant gamatex warping machine, each piece of yarn is also measured and aligned one after the other. It helps fabric to become stronger and this also maintains its color and pattern.

Combining a firm turkey texture that not only provides durability but also looks good, and work done during warping in the making process pays high dividends. This is beneficial for both manufacturers and customers as it leads to a higher satisfaction rate with the end product.

In addition to these Prashant Gamatex and ProfixM machines simplifying the weaving process, productivity also increases. It helps in avoiding the issues like what happens if we don't prepare Yarn correctly. This is important for preventing yarn breaks, because workers can check and control how tight the yarn is in preparation.

Gamatex prashant warp machines deliver dyeing yarn effective spend esteem. These are very precise measurements and the factories do not take into account how much waste yarn they want to save. profixM prashant warping machine leads to fabric factories being able to make more of a good fabric with less great yarn and besides it is cost effective, expanding woven production capacity & minimizing even the organic waste.

research and development department is the top quality. We have been providing yarn machines for more than 12 years. We keep up-grading technology. Additionally, we have 30,000m2 of machine production workshop and 20,000m2of nylon/ polyester production workshop.team Prashant gamatex warpingto providing you with supreme quality machines. Every member the team is committed to their work and accountable their daily job. We truly hope that our expertise and technology will yield greater quality of work.

factory team has been customer- Prashant gamatex warping, they are well aware that customer needs satisfaction are key to success of the company. They actively listen the voices of their customers, as well as optimize production service satisfy their requirements and expectations.

sectional mother-yarn splitting warping machine produce even tension beam with 550m/minsspeed on nylon mother yarn.also Prashant gamatex warpingthe first machine can make polyester dty mother yarn.Our products are easy install, simple set up, easy use and have minimal expectations for workers.

company was founded in year 2013. Our company sold 300 products over last 11 years, and we are the market leading company. business is a Prashant gamatex warpingcompany that is involved in the design, manufacturing, and sales of split warping machine and yarn. team of factory workers has professional skills and experience.