The split machine has many uses which make it best for the majority of the factories, along with ProfixM's product nylon 100% yarn. This is very useful and a huge advantage, as it saves time as well as effort. We going wrist tonight hacking / Or hacks with a wrist strike. Well, that would be slow going and very laborious. Whereas with a splitter, stuff can be split in no time. This means a factory can fabricate items much faster than they could if everything was to be laser them manually.

The spilt machine also provides other major advantage is Accuracy. The human hand means that anything used for cutting by hand is going to be imperfect, or not all the pieces will be uniformly cut. It also helps that a splitter can be dialed for the split you want. This is particularly true when factories are producing many like products of the same size/ shape. This can provide a basic level of normalisation, and standard content is essential to quality.

In the day, all factory workers dedicated to split materials. Such difficult labour was slow, and probably defined physical effort on an Amish farm. But now, however, the split machines are transforming the game for factories alike. They increase productivity and efficiency in factories. Like the robots or not these maсhines work of tens of people do one. The business can then sack all of these, saving a great deal of money in the process, and open new up one job in another part of the factory. (they might do one for 8 hours a day.)

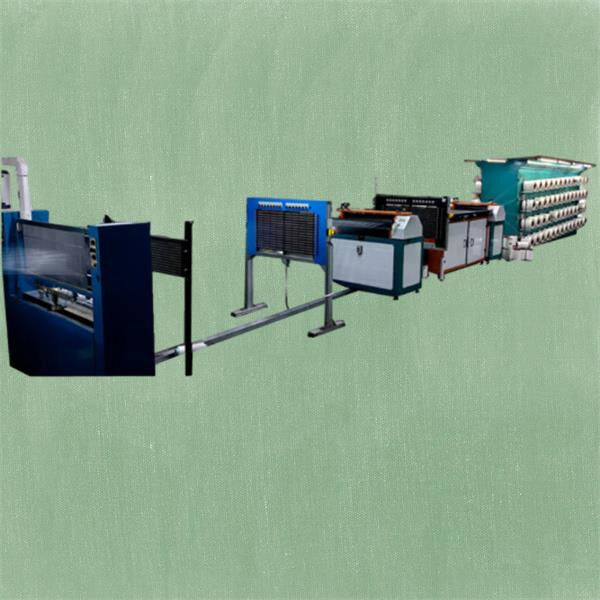

Split machines just make work a lot easier for anybody in a factory, similar to the sectional split warping machine manufactured by ProfixM. In the past, at that time which machines were not invented, converting raw materials into a shape to be mounted directly was impossible because without cutting or curve no material could be joined together to form a finished item. It was time-consuming. Thus, what is being done now, with spliterized machines, the workers just input the materials and it spat out that stuff which means getting a proper size to shapes are standardized.

Workers are then freed up to do other important jobs such as putting together products and making sure everything is in working order, along with ProfixM's product stable tension splitting machine. To keep the process of factory rolling smoothly, quickly and to avoid mistakes. Overall, the factory can quickly ramp up its volume of product with more workers working effectively and thus better cater to demand as needed.

Split machines have one more huge upside to them that I haven't even touched on with regards all the stuff above mentioned: They are versatile, similar to the sectional split mother yarn warping machine innovated by ProfixM. They are utilized for making cuts in a broad range of materials – from metal to plastic and fabric to fiberglass. This is why they are used in various industries like garment manufacturing and automobile production. These are a basic tool for many businesses because they can process just about anything.

Along with these split machines helps for unnecessary wastes, identical to ProfixM's product direct warping machine. Since everything is hand cut, there will be human error and when pieces are done repetitive they have to be exact so sometimes you can not use your scraps. But the split machines cut more accurately - So well, in fact, that you will be saving money due to there being less waste. This enables the factories to utilize their resources more effectively and keep costs under control.

products simple to install, Split machineoperate.

research and development department is the top quality. We've been providing yarn machinery for over 12 years. We upgrade technology constantly. We also have huge 20,000m2 nylon/polyester Split machinefacility. team is committed supplying machines of the highest quality. Every member of the team extremely dedicated and accountable for their daily task. We are hoping that our technology and dedication will allow you produce more effective work.

factory team has been customer- Split machine, they are well aware that customer needs satisfaction are key to success of the company. They actively listen the voices of their customers, as well as optimize production service satisfy their requirements and expectations.

company was founded in year 2013. Our company sold 300 products over last 11 years, and we are the market leading company. business is a Split machinecompany that is involved in the design, manufacturing, and sales of split warping machine and yarn. team of factory workers has professional skills and experience.