Do you ever think about how your favorite clothes are made? It’s really interesting! So, at the risk of sounding like a complete tit, clothes are difficult to make, but on a less murderous note it is plain to see that by making simple materials into poignant pieces of fabric. Warping: It seems a native process too many, but in the grand scheme of production there is quite a bit that goes into it; most receiving lightning speed tempo change outsourcing.

Warping is the process of aligning (weft) yarns, or long strands of threads on a special beam to create what is called a "warp. A warp is a series of yarns which moves up and down in a fabric. With the proper profixM high speed warper, textile workers can create fabrics that are tougher, more durable and suitable for a variety of different applications. Affect how the fabric will feel and look by where you laid your yarns.

The process of weaving warps has been an important part in the creation of fabrics even hundreds of years ago. The profixM warping machine yarn assist the workers to do a great job in textile as well. With modern machines such as those made by ProfiXM, workers can create fabrics with a lot more detail and precision that ever possible in the past. The fabrics are even better as a result, and the machines can do things that used to be very difficult to do by hand.

Ways of doing warping are too many and each one has its own advantages. These include sectional warping, direct warping, and beaming. This is called sectional warping which means putting the yarn small sections to beam. It keeps things organized. Direct warping is winding your yarns directly onto the beam without any type of lease, which tends to be faster. Beaming is the winding of all the yarns onto a big cylinder or beam and can be a very efficient way to make high amounts of fabric.

One of the fun things about warping is that to distort, fabric tends to be really special and unique. When these yarns are then manipulated in various configuration, we can get magical patterns and interesting textures that add to the beauty of the cloth. This is particularly relevant in the world of fashion, where people always desire a new trend or styling. It was with warping that we could create fabrics that looked good, and naturally beautiful to wear.

Warping contributes to better quality of fabrics while enabling factories to work faster and easier. Textile companies can produce larger quantities of fabrics in a reduced amount of time by utilizing profixM Sectional split warping machine for warping purposes. This majorly influences their ability to keep prices down and in turn, sell cheaper clothes to the broader consumer base. A factory that is quicker at its job also translates to faster style turnovers for consumers.

company was established in year 2013. We've sold over 300 products over the last 11 years, we are the market leader. Our company is a highly-specialized firm that designs, produces, sells split warping Warper textileand yarn. team at our factory is extremely skilled experienced.

supply yarn and machine more than 12 years and are a top research development department. continue new Warper textileupgrade. also have 30,000m2 of machine production workshop 20,000m2 of nylon/polymer production workshop.Our team is dedicated providing you with the highest quality machines. Every member our team is responsible for the work they do. We sincerely hope that our technology and efforts can help you achieve greater quality of work.

Warper textileteam has always been customer-centric team, and they well aware that customer requirements satisfaction are crucial for the success of enterprise. They listen closely to the voices their customers, as well as optimise production and service satisfy their needs and expectations.

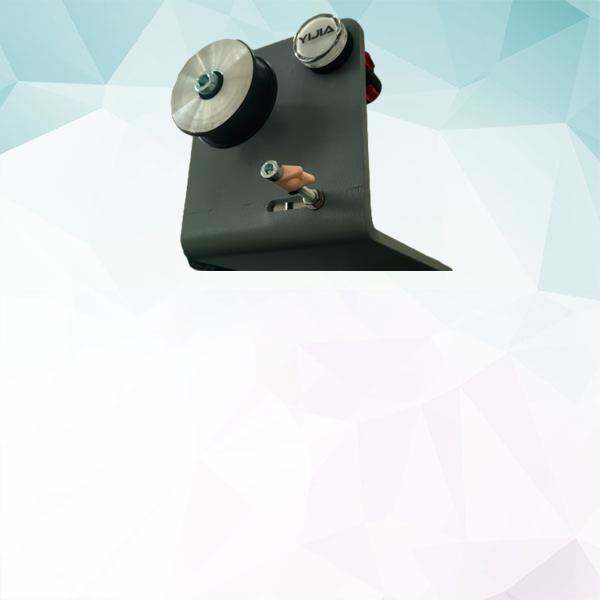

sectional mother-yarn splitting warping machine produce even tension beam with 550m/minsspeed on nylon mother yarn.also Warper textilethe first machine can make polyester dty mother yarn.Our products are easy install, simple set up, easy use and have minimal expectations for workers.