Warping machine is a special weaving tool and it has an important role in fabric making. It makes sure that the threads of the cloth are straight and uniform. It is essential for producing the fabrics of a quality that people wish to buy. Well-made fabrics look smart and last for ages Warping machines perform a delicate task, and their indispensability can be gauged in the textile industry where clothes and other fabric stuff are manufactured. Now that you see what we mean, let us learn a bit more about profixM warping machine yarn and the reason why they are imperative for every weaving business!

What are Warping Machines? A warping machine is an apparatus that contributes to the production of threads which are in turn used for manufacturing different kinds of fabrics. There make something called a warp. The warp are the threads that run up and down in a woven fabric. To make a fabric that is really good, you must have a warp which has high strength and good approximation. So that the weft and warp are not too far apart, because otherwise your fabric will looked warped and even tear easier. It is really difficult to make a good warp according to the requirements of fabric maker without having proper warping machine. In that case, the fabric quality would suffer and customers could be disappointed with the end product.

The fabric making process of Warping Machine is key to everyone. It ensures the threads are evenly spaced and that they will be perfectly even to weave with. Warp threads count the vertical threads and weft threads are the horizontal threads that go over and under these Warp Threads. This process repeats many times as a strong and nice looking weave of cloth is formed. Without the use of a warping machine, the warp would not be even. This would result in a fabric that looks bad and is very non-durable.

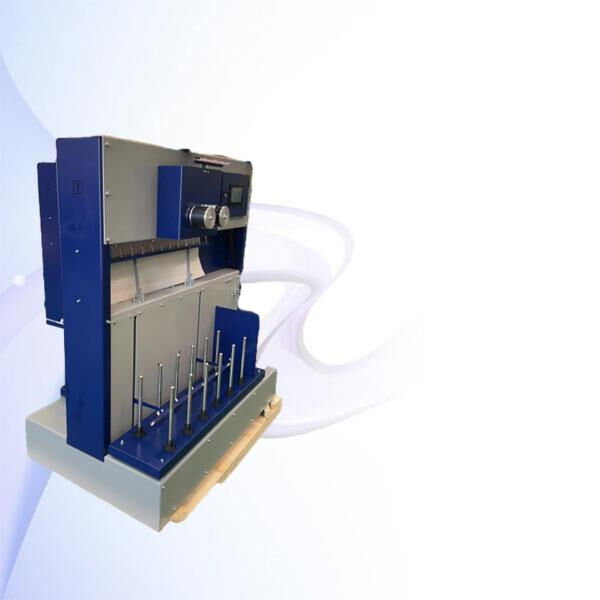

The warping machine is a simple and fast (which equipment’s needs to be operated by only warping people) It’s a complex equipment which demand special abilities for successful operation process. It is made up of several components which work in unison, such as a creel, warp beam and tensioning unit. The section that the threads reside on as they are being worked is called a creel. profixM high speed warping machine which holds the finally prepared warp for next processing steps. With weaving loom, you have the option to put tension in the warp threads to maintain proper separation and even pressure needed for a good piece of fabric.

A warping machine is used to pass the process, by placing the yarn in the creel. The yarn is then pulled by the machine and fed through a reed which divides it into the correct number of threads. The threads are then transferred to the warp beam and tensioned properly with all ends pulled exactly onto that thread, in specific order. After the warp is finally ready and housed correctly, it comes off of the machine and can be sent to a loom to be woven into fabric.

Silk is an elegant and very delicate fabric, as a result, requires especially dedicated ones. But it is best suited for warping silk as these require thread to be spaced evenly else they cause straight lines or interfere with the selvages of cloth. This makes certain that the silk cloth is of high exceptional and suits into the expectations of those who buy it. The attraction among people for silk arises from the beauty and softness of the material, so if a fabric ends up losing its weight, it might stuck away as far as possible.

Over the years, ripping machines became more advanced. Powerful new technologies enable today's machines to be better, and run faster than yesterday. Nowadays warping machines are available which are provided with sensors to monitor the tension and speed of warp. These sensors are used to take surety that the dash of fabric is perfect. profixM sectional beam warping also support operators in promptly making changes if something seems to be off.

company was established in year 2013. We have sold 300 products over last 11 years and remain the market leader. Our company a highly skilled company that is involved in the design production, manufacture, and sale split warping machines and yarn. factory team has rich Warping machineskills and knowledge.

sectional mother-yarn splitting warping machine produce even tension beam with 550m/minsspeed on nylon mother yarn.also Warping machinethe first machine can make polyester dty mother yarn.Our products are easy install, simple set up, easy use and have minimal expectations for workers.

factory team is extremely customer-centric recognizes that the success a business is dependent on the needs satisfaction of its customers. They Warping machinelisten the voice of customers and enhance their service production in order satisfy their requirements and expectations.

have been providing yarn machines for more than 12 years. have top-quality research and development department. We constantly upgrade our Warping machine. Also, have a 20,000m2 nylon/polyester manufacturing workshop. staff is committed to supplying machines of the best quality. Every member the team is extremely dedicated and accountable for all of their job. We are confident that efforts and technology will result in more efficient productive work.