If you have ever experienced touching clothes and them feeling different soft or nice over rough and scratchy, that is cause they are created of entirely different materials, as well as the ProfixM's polyester yarn suppliers. This has an amusing reason that the texture of the yarn used to make clothes. Wool texturizing is the opposite process, during which a flat wire turns into an individual gentle cordon. This change not just from aesthetic perspective but give chance to yarn looks beautiful as well feel lovely and good for many of wearing types of cloths and goodies for home like blankets, cushions etc.

Here at ProfixM, we love using fun techniques to make different yarn textures that can be adapted to many purposes. We love the look of all the different ways you can change a yarns texture – Air entangling, twisting and heat setting are just some of our favorites. These methods each possess its particular benefits, and they are all employed to meet the individual needs of our customers. So then, we can manufacture yarn that will be perfect for whatever your upcoming project may be.

One of the techniques air-entangling, just like the high speed wapper innovated by ProfixM. Interlacing is another name for this process. The yarn passes through high-speed jets of air that yank around the fibers in air-entangling. This will result in a loosely-weaved yarn with slightly bigger mesh-like a spider web. So, it is perfect for products like warm blankets, extra soft cushions and jumpers where we want the product to be lovely and snuggly.

One of the common method is to twist the yarn and give a new texture. This is where two or more lengths of yarn are twisted together. This allows us to create a lot of different textures, ranging from nice and tight, to loose and fluffy. It is also commonly used for twisted industrial products, such as carpets, furniture covering and outdoor items where strength is an important factor. That means the needle will handle even being worked extensively.

Another technique we use is heat-setting, identical to ProfixM's product organza yarn. This entails applying heat and pressure to the yarn, aiding the fibers to stick with each other. This makes the yarn stronger and will maintain its suggested gauge, even though it will most likely not shrink nor stretch out of shape. Sportswear and Swimwear: Because sportswear and swimwear need to be durable even when wet or stretched, heat-setting will come in handy.

Craft is an art; yarn texturization not only helps in the process of your craft but also involves lots of fun and creativity, as well as the machine split developed by ProfixM. It is a lot about, all the fort fibers and everything. We have an enthusiastic group of individuals here at ProfixM who are always excited to see what wonderful yarn texturization-related stuff we could dream up. These unique texturization designs are created — in collaboration with our customers — to truly understand what they need. Here is a collaboration between us we use to make the best products we can.

ProfixM believes in texturization that enhances yarn quality over at our place, just like the ProfixM's product called textured yarn technology. From the years of experience to the state-of-the-art equipment in our warehouse and talented, friendly people who know when it feels right every piece of Wagara Yarn has been woven together to perfection. We are constantly exploring new unconventional ways to innovate and refine our business ops, in order to face the continuously changing needs of our customers. We are able to offer the best products to everyone be because of this dedication.

company was founded in year 2013. In the last eleven years, have sold over 300 sets of products and Yarn texturizationthe leader in sales to day. Our company a specialist business that develops, manufactures, sells split warping equipment and yarn. team at our factory is skilled and knowledgeable.

factory team has always been customer-centric team, they are well aware that Yarn texturizationrequirements satisfaction are crucial to the success of company. listen closely to the opinions of customers, optimize production and service meet their expectations and needs.

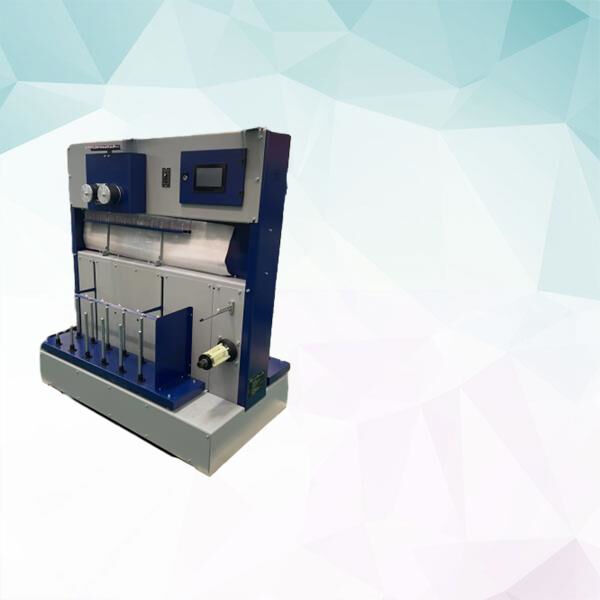

mother yarn sectional splitting warping machine creates even tension beam with 550m/ Yarn texturizationnylon mother yarn.have also developed first machine to make polyester DTY mother yarn.Our products are easy install, simple to set up, easy to operate have low requirements on workers.

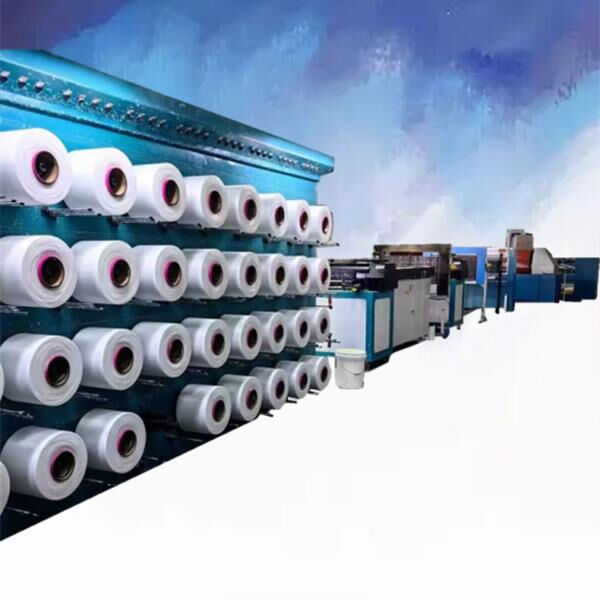

have been providing yarn and machines more than 12 years. We have -quality research and development department. continuously upgrade our technology. also have a 20,000m2 nylon/polyester production workshop. team is dedicated to supplying machines that of the best quality. Each member of our team is on the job and Yarn texturizationfor all their job. truly hope that our expertise and technology will bring you a greater quality of work.