- Overview

- Inquiry

- Related Products

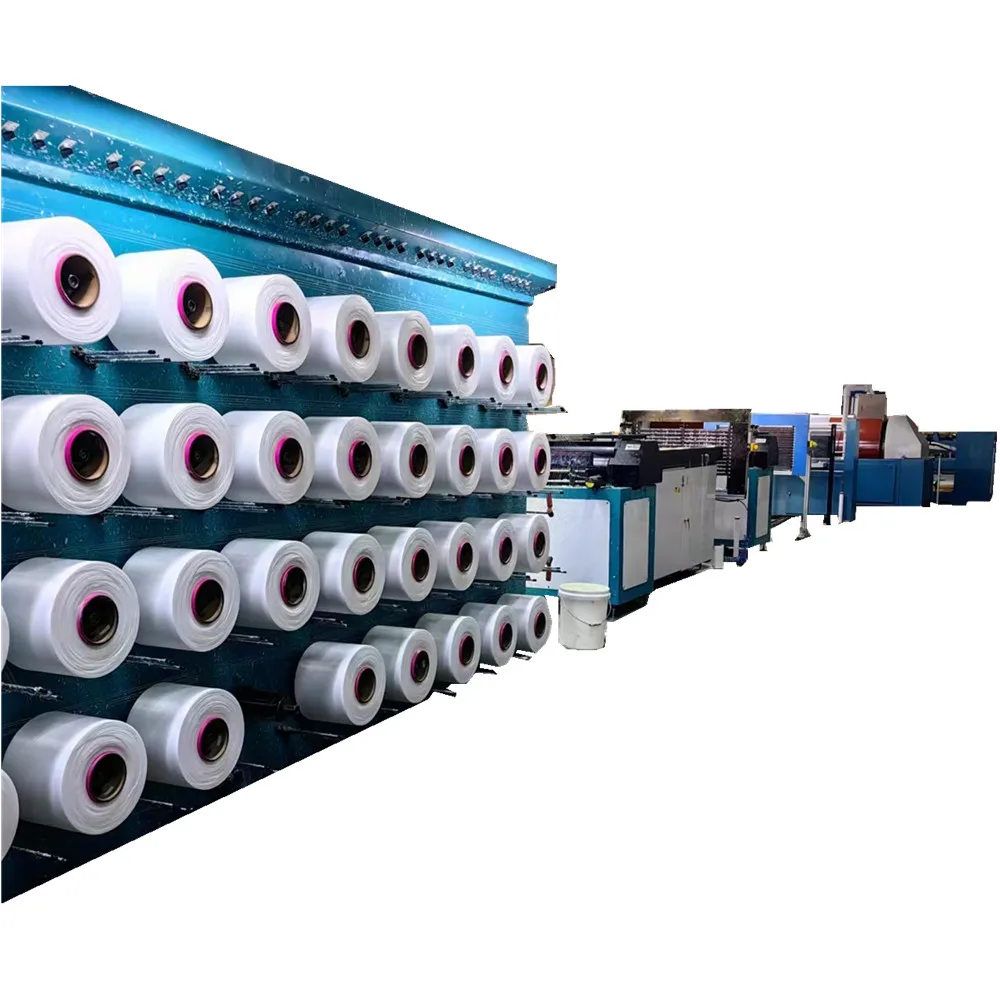

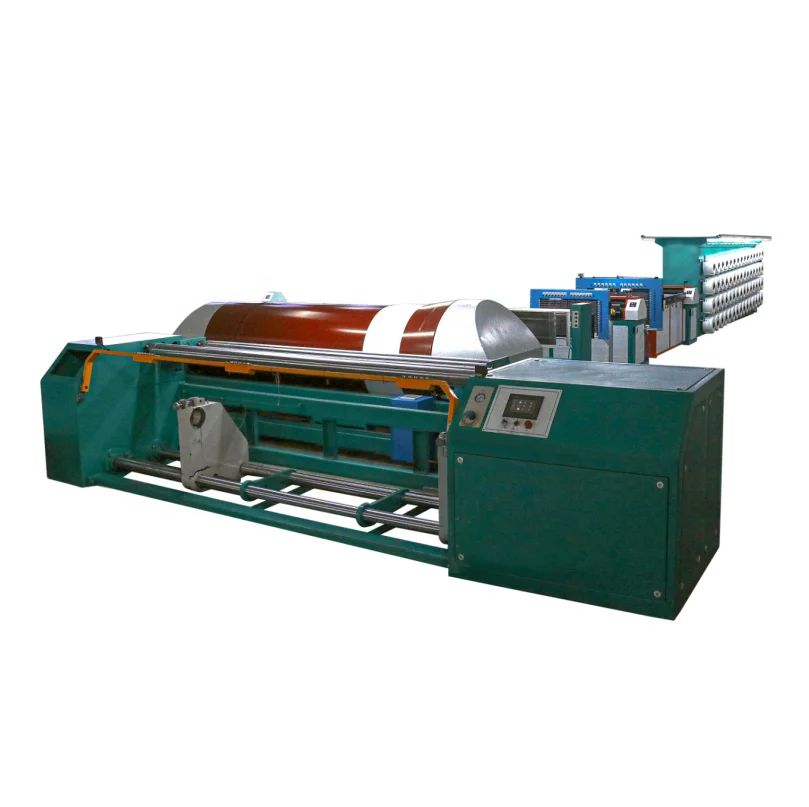

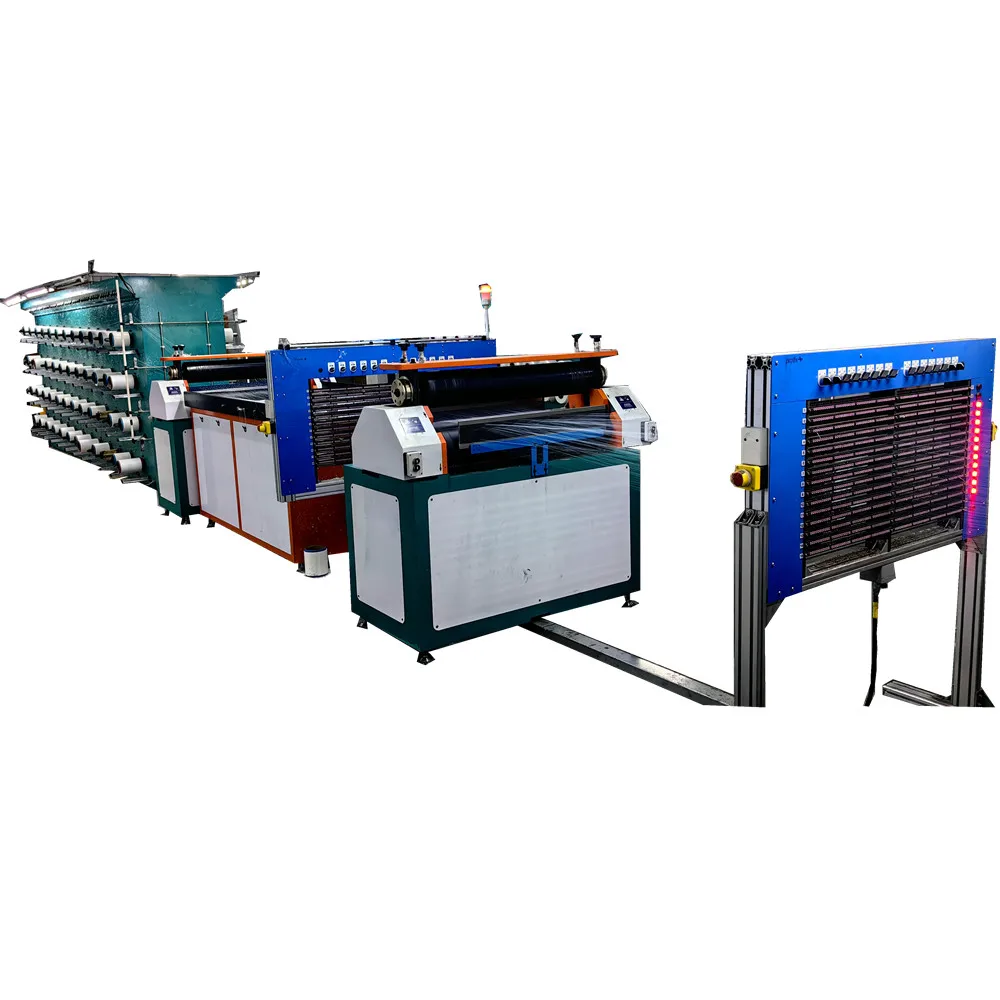

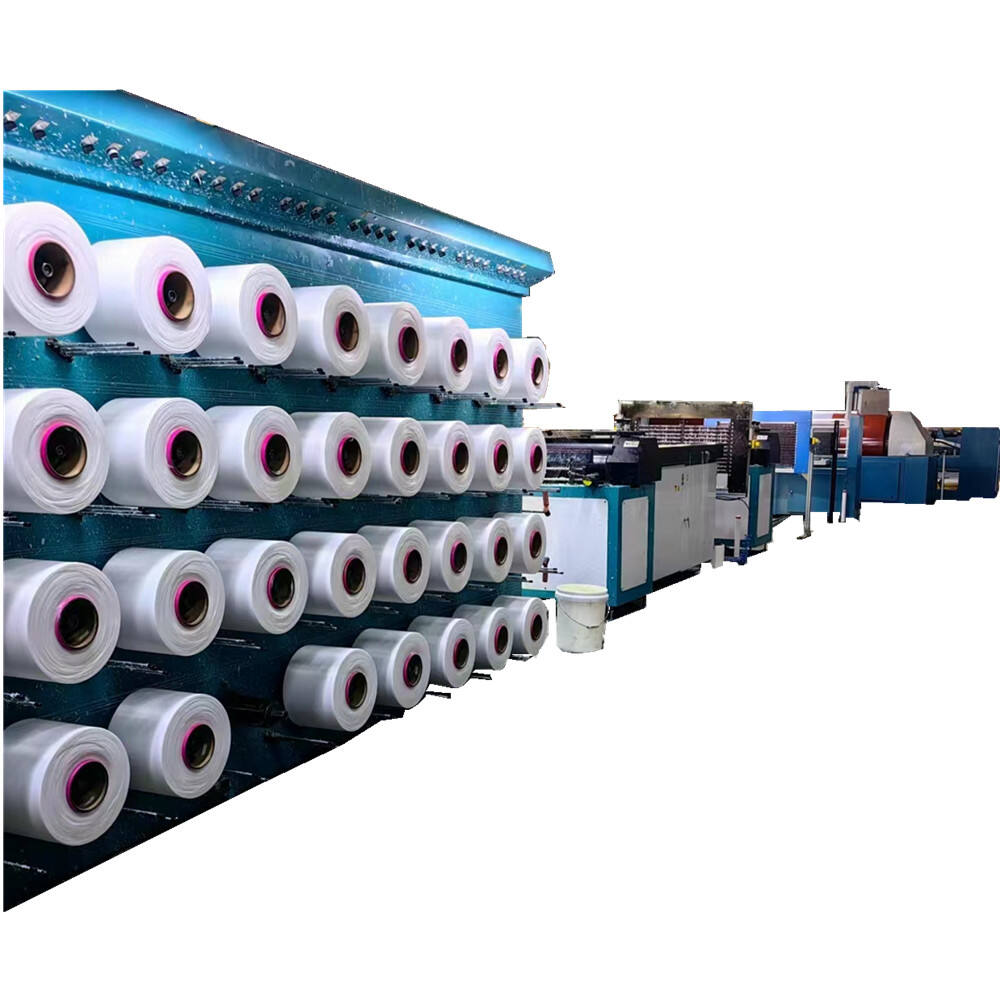

Introducing the latest innovation in woodworking technology: the Splitting and Warping in One Machine. This state-of-the-art machine is designed to help weavers increase their productivity and efficiency while reducing their workloads.

With all the Splitting and Warping in One Machine, you are able to divide and warp your yarns at high rate, allowing for you to definitely create more production in less time. This device is good for weaving companies that are trying to enhance their manufacturing lines and workflows.

The Splitting and Warping in One Machine was created having a program that is user-friendly rendering it an easy task to run, also for newbies. This device has an array of advanced functions that allow one to personalize it to satisfy your requirements which are certain demands.

One of many standout options that come with the Splitting and Warping in One Machine is its abilities being high-speed. This device can run at unmatched rate, letting you complete your projects faster than previously. The Splitting and Warping in One Machine are designed for heavy-duty tasks with simplicity, providing you the reassurance you will need to concentrate on your projects having its seamless procedure.

Furthermore, the Splitting and Warping in One Machine consists of top-notch materials, ensuring its durability and durability. Its sturdy constructions implies that it could withstand usage that is hefty stay in perfect condition even with many years of usage.

The Splitting and Warping in One Machine is equipped with some of the most advanced technologies available in the market today. Its automation features make it possible to split and warp yarns of different sizes, shapes, and thicknesses with high precisions. This ensures that you get consistent results every time you use this machine.

So why wait? Invest in the Splitting and Warping in One Machine today and take your weaving to the next levels.

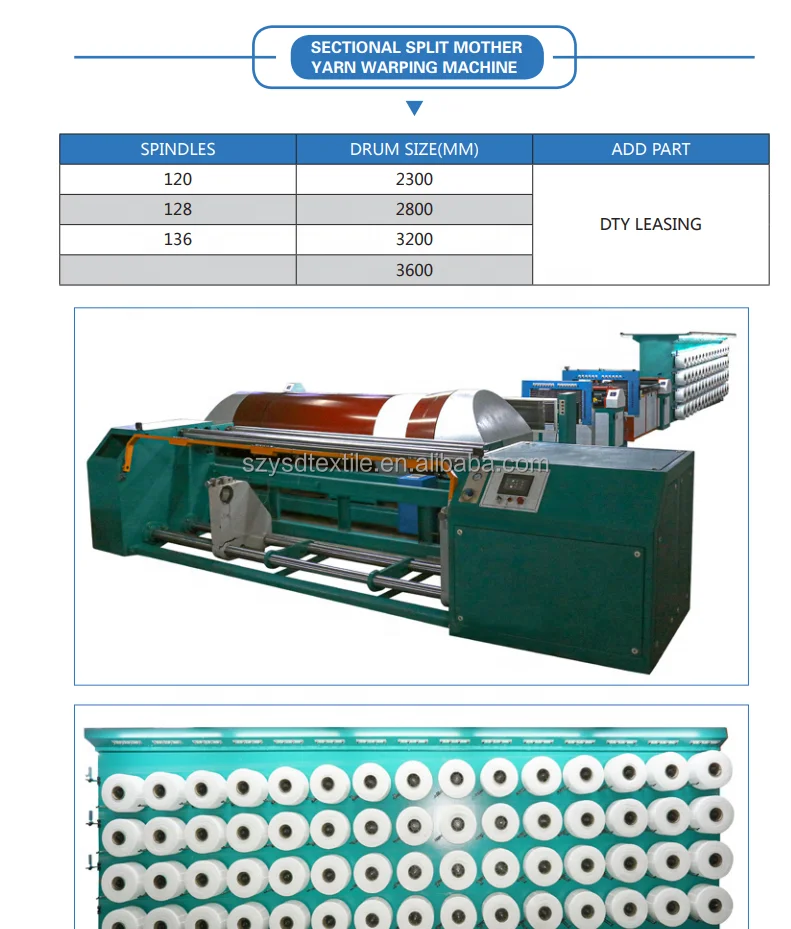

item | value |

Applicable Industries | Manufacturing Plant |

Weight (KG) | 13500 |

Showroom Location | None |

Video outgoing-inspection | Provided |

Machinery Test Report | Provided |

Marketing Type | New Product 2023 |

Warranty of core components | 1 Year |

Core Components | Engine |

Place of Origin | China |

Jiangsu | |

Machine Type | WARPING MACHINE |

Product | MACHINE |

Material Capabilities | NYLON/POLYESTER MOTHER YARN |

Condition | New |

Warranty | 1 Year |

Name | NYLON POLYAMIDE POLYESTER MOTHER YARN WARPING MACHINE |

Usage | 1t/day 240D/12F SD |

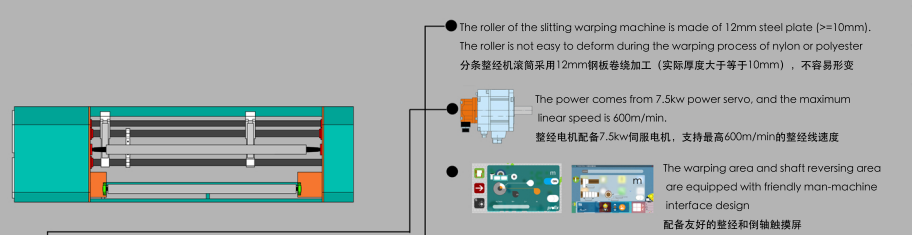

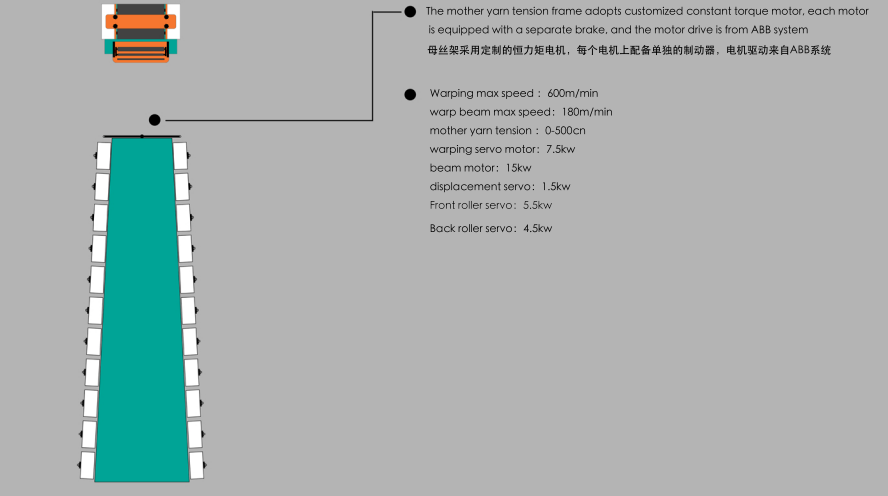

Warping max speed | 600m/min |

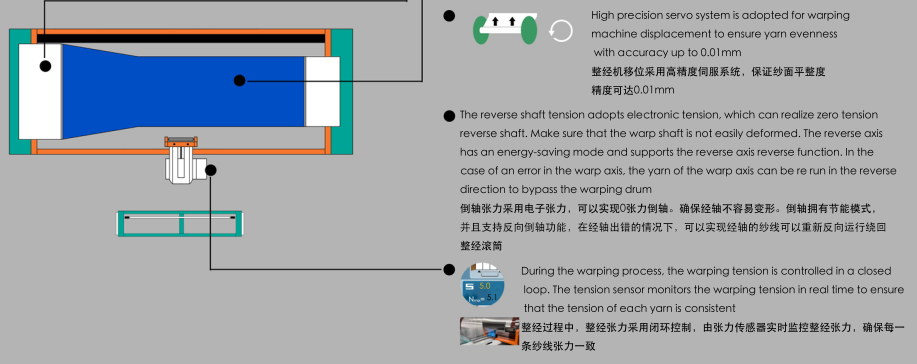

mother yarn tension | 0-500cn |

warping servo moto | 7.5kw |

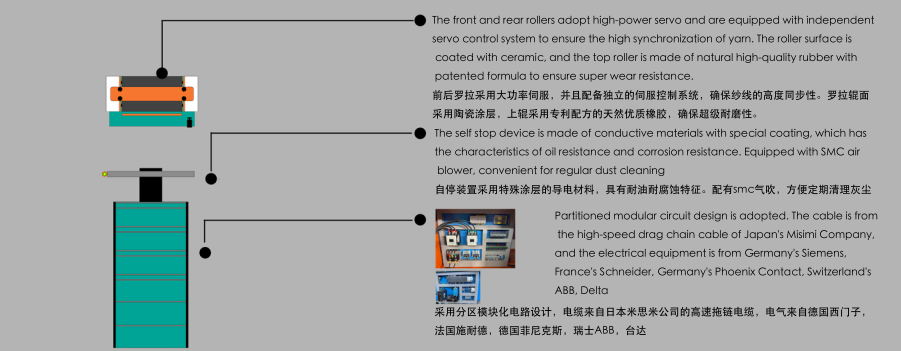

beam moto | 15kw |

warp beam max speed | 180m/min |

displacement servo | 1.5kw |

Front roller servo | 5.5kw |

Back roller servo | 4.5kw |

Mother yarn warping machine

No | Item | Data | ||

1 | Warping max speed | 600m/min | ||

2 | warp beam max speed | 180m/min | ||

3 | mother yarn tensio | 0-500cn | ||

4 | warping servo moto | 7.5kw | ||

5 | beam moto | 15kw | ||

6 | displacement servo | 1.5kw | ||

7 | Front roller servo | 5.5kw | ||

8 | Back roller servo | 4.5kw |

1. Who are we?

We are based in Jiangsu, China, start from 2000, sell to Southern Europe(15.00%), North America(10.00%), Southeast Asia(10.00%), Mid

East(10.00%), Central America(10.00%), South Asia(10.00%), South America(5.00%), Eastern

Europe(5.00%), Africa(5.00%), Oceania(5.00%), Eastern Asia(5.00%), Western Europe(5.00%), Northern Europe(5.00%), Domestic

Market(5.00%). There are total about 5-10 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Mother yarn Warping machine, Steel buckle

4. Why should you buy from us not from other suppliers?

null

5. What services can we provide?

Accepted Delivery Terms: null;

Accepted Payment Currency: null;

Accepted Payment Type: null;

Language Spoken: null

EN

EN

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RO

RO

RU

RU

ES

ES

ID

ID

UK

UK

VI

VI

TH

TH

TR

TR

BN

BN

NE

NE